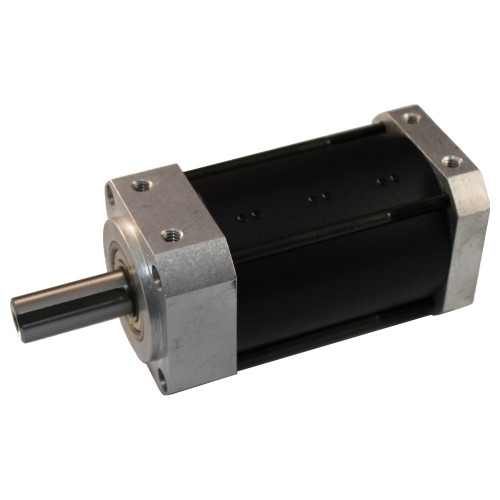

Heavy Duty P8H Gearbox with a 1728:1 reduction. Configured with a 1-1/2in long x 5/8 round output shaft, stock square front block, hard black anodized aluminum ringgear, and a selectable input bundle.

Zebra Gearbox

This gearbox is manufactured by Zebra Gearbox. This is a standard configuration from the Zebra P8 line, for more options and built to order configurations please visit ZebraGB.com.

INPUT

All motor input selections include a motor block, pinion, and hardware (screws/washers) to mount the selected motor. Machinable selections include a motor block and a pinion ready to machine to a custom motor. Additional Motor HW Kits and Pinions may be purchased separately. Links to items that will work with gearbox can be found in the Specifications tab.

-- CIM Motor --

Motors with a 8mm keyed shaft and a 3/4in boss.

Motors with this configuration include the FIRST CIM Motor and the REV NEO

The pinion is a slip on to the shaft and uses a key

-- Hex Input --

Input block with an integral pinion shaft. Allows the gearbox to be driven from the input using a pulley, sprocket, or handle mounted to the pinion shaft. The input pinion shaft is supported by two R8 bearings and provides a 1/2in hex with a #10-32 end tap to make mounting to it easy. This input also makes it easy to back drive the gearbox and use it to increase speed. (Back driving no recommended for high reduction gearboxes)

-- Machinable Motor Block and Pinion --

Machinable motor block with side mounting holes.

Machinable pinion ready to bore to required size.

SOME ASSEMBLY REQUIRED

Gearbox will be delivered assembled and tested; however, it will need to be disassembled to grease and mount the motor prior to use. No special tools are required, typically only an allen wrench.

GEARBOX MUST BE GREASED

Prior to use the gearbox must be greased, grease IS NOT INCLUDED and must be purchased separately. We recommend Mobil XHP 222 Special grease; however, most lithium based ball bearing grease can be used. We do not sell grease separately, it can be readily purchased from most local auto parts stores or online suppliers such as MSC, Grainger, and McMaster among others. Configurable and Custom gearboxes can be supplied greased.

MAXIMUM TORQUE RECOMMENDATION

Please reference the maximum torque for the gearbox in the Specifications Tab. The torque given is the FAILURE torque measured at the OUTPUT shaft from destructive bench testing. The torque driven into the gearbox, the gearbox reduction, and an appropriate safety margin should be considered when evaluating the torque in a given system.

- Reduction:

- 1728:1

- Height/Width (Square):

- 2.5 in

- Fits In Diameter:

- 3 in

- Length:

- 4.75 in +Shaft +Input

- Weight:

- 3lb 1.3 oz +Input

- Max Torque:

- 280 ft-lbs

- Planet/Sun Gear Material:

- Cold Rolled 4140 Alloy

- Gear Specs:

- 0.8mod, 20deg PA

- Stages:

- 6 - 4:1, 4:1, 4:1, 3:1, 3:1, 3:1

- Mounting Holes:

- Eight Total: 1/4-20 Thread

- Shaft:

- 5/8in x 1-1/2in

3/16 key

1/4-20 end tap

- First Stage:

- 4:1

- Motor HW Kits:

- P8 4:1 Motor HW Kits

- Pinions:

- P8 4:1 Pinions

Model shows stock configuration with a Machinable Motor Block - 1/2in Thick